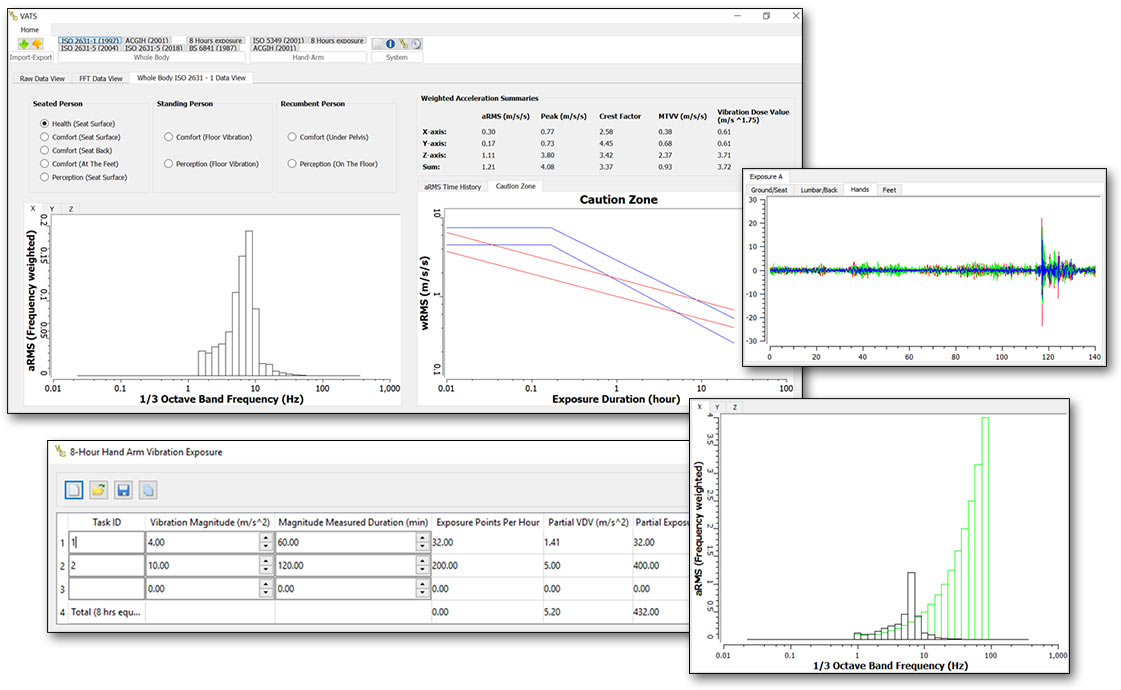

VATS™ (Vibration Analysis ToolSet)

Concern for the hazards related to exposure of the human body to vibration from power tools, vehicles and machinery has increased in recent years. Both whole body vibration and hand arm vibration can cause physical damage and considerable increased compensation costs. Various standards have been implemented to address this important hazard area. The VATS series of human vibration analysis products has been developed to enable organizations to easily obtain vibration data and compare them to the various standards.

Leading organizations worldwide use VATS. These include vehicle and tool manufacturers, government organizations, universities, corporations and consultants. VATS unique features include the ability to handle multiple accelerometers and other sensors with large amounts of storage that can then be easily analyzed by our powerful yet easy to use software.

Key VATS Features

- Multiple tri-axial accelerometers can be connected

- 8 channels can be expanded to 24 channels

- Other sensors such as force sensors and joint angle sensors can be connected

- All raw data is stored on Micro SD cards with 2GB of storage memory available

- Powerful and easy to use analysis software

Comprehensive Human Vibration Analysis Solution

The VATS series of human vibration analysis products are available as individual packages for either hand-arm or whole body analysis. The VATS includes the MWX8 DataLOG that is a fully portable, subject worn, programmable data acquisition unit. The DataLOG collects data from the accelerometers and/or from a variety of additional sensors such as electrogoniometers, force sensors and EMG that is then downloaded to a PC for detailed analysis.

DataLOG has a maximum sampling rate of 20,000Hz/channel (160KHz maximum on 8 channels), 2GB flash and telemetry option. Up to 3 DataLOG units can be synchronized for a total of 24 analog channels. The DataLOG is connected to the host PC for both programming and downloading of data. Data for X, Y and Z axes of the accelerometers is simultaneously collected. When recording in MMC Mode only synchronization options for 16 or 24 channels are available with sampling rates up to 20,000Hz per channel (160KHz total Sampling frequency).

DataLOG has a maximum sampling rate of 20,000Hz/channel (160KHz maximum on 8 channels), 2GB flash and telemetry option. Up to 3 DataLOG units can be synchronized for a total of 24 analog channels. The DataLOG is connected to the host PC for both programming and downloading of data. Data for X, Y and Z axes of the accelerometers is simultaneously collected. When recording in MMC Mode only synchronization options for 16 or 24 channels are available with sampling rates up to 20,000Hz per channel (160KHz total Sampling frequency).

With the VATS, the user can either perform detailed analysis with full reporting on a local PC or send the data electronically for analysis at a central corporate site. This approach simplifies data collection and incorporates sophisticated analysis with user-friendly software and comprehensive help. Raw data is available for analysis.

A real-time clock is included in the DataLOG to enable every recording to be marked with an accurate start date and time with its duration. A switch-mode power supply is used to obtain the maximum life from a set of two inexpensive AA batteries.

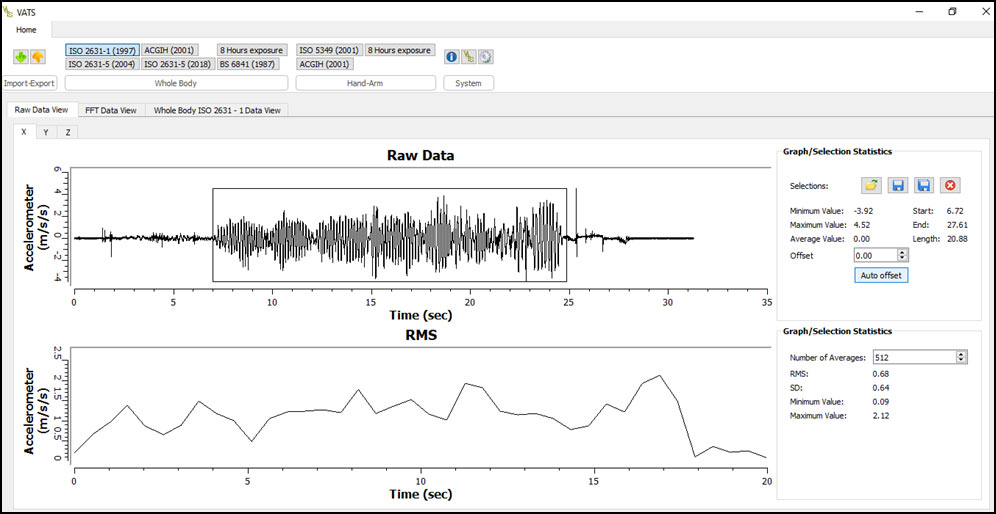

The VATS is available for either hand-arm or whole body analysis. Hand-arm vibration analysis is based on the ISO 5349 and ACGIH standard for hand arm vibration (HAV). Whole body vibration analysis is based on the ISO 2631-1, 2631-5 (2004), 2631-5 (2018), BS 6841, and ACGIH standard for whole body vibration (WBV) and 8 hours exposure.

Software Features

Data Analysis performed:

- Fast Fourier Transfer

- 1/3 Octave band analysis

- Weighted and unweighted RMS

- Band-pass Butterworth filter

- Filtering window

- Spectrum plot

- 1/3 octave band plot

- Crest factor

- Vibration dose value

- TLV/Caution zone value for ISO and ACGIH standards

- RMS history and summaries

- PSD (Power Spectral Density) Periodgram and Welch methods and their parameters

- Ability to fine-tune the data selection windows from the graph and from a floating window.

All calculated values and graphs can be exported in ASCII, PDF or HTML formats.

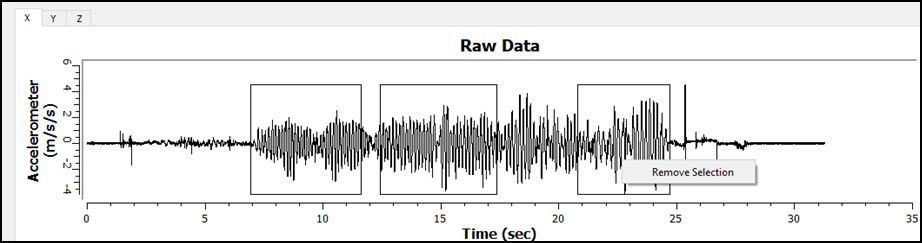

Users can select one or more data ranges by using the mouse and left-clicking and dragging to select the desired data points. The selected data points will appear in the RMS graph below the Raw Data. This process can be done multiple times to select different data points. All the data points will then be combined for the analysis.

You can easily remove a data selection, by simply right-clicking on it and selecting Remove Selection.

Examples of Selected Analysis

Click here to see more screen shots.

Optional Accessories

Ident Switch IS3

A 1.8 meter (6 ft) cable with a suitable connector at one end to connect to the DataLOG, and a hand held switch at the other. This useful accessory allows time marks to be superimposed on the recorded data enabling the operator to highlight specific events during data collection.

Synchronization Cable SYNC1

For remote start/stop by a signal sent from other hardware systems to synchronize data collection from multiple sources. The SYNC1 is a 2 meter (6.6 ft) cable with a connector at one end to connect to the digital input socket of the DataLOG and 2 flying wires at the other end.

Synchronization Cable SL100

Synchronization cable SL100 is used to synch two or three MWX8 DataLOG units. One SL100 is required to synch two DataLOGs, two SL100s are required for 3 DataLOGs.

A250 Cable

This cable is an extender cable for users who want to use two axis of a 3rd accelerometer on a single DataLOG unit (i.e. for connecting to analog channels on the opposite side of the DataLOG unit). This is only applicable to Series 2 accelerometers.

VATS Specifications

DataLOG MWX8

Dimensions: 104 x 62 x 22 mm

Mass: 129 g

Battery type: 2 x Alkaline AA, LR6, MN1500

Battery life: 5-11 hours nominal depending on sensor type & quantity

Microprocessor controlled programmable gain amplifiers

Analog channels: 8

Digital channels: 4

Memory Internal: 2GB Micro SD card

Bluetooth® Adaptor: Microsoft Bluetooth® stack compatible

Front end ADC: 14 bit giving ± 4000 counts resolution

Recording modes: record to Bluetooth® & Micro SD card, record to Micro SD card only,

record to Bluetooth® only

Range of Sampling frequency per analog channel: 1, 2, 5, 10, 20, 50, 100, 200, 500, 1000, 1250, 2000, 2500, 5000, 10000, 20000 Hz (Note: Bluetooth is used for monitoring only at the higher sampling rates)

Bandwidth:

Input Range 1mV and 3mV, Bandwidth DC to 1KHz (+0 dB / -3dB)

Input Range 10mV to 3V, Bandwidth DC to 10KHz (+0 dB / -3dB)

an automatic anti-alias digital filter: approximately -3dB at 0.45 x sampling rate and a maximum attenuation of -13dB above 0.8 x sampling rate

Power supply per channel: adjustable 0 to 4.6 Vdc

Current supply per channel: ≤20 mA

Accuracy: better than ± 0.5% full scale

Maximum common mode: 1.2 V

Series 2A Accelerometers

Product #: S2A-16G-MF

Dimensions: L x H x W (29.50 x 11.60 x 15.30 mm)

Mass: 15 grams

Enclosure: Aluminum grade 6063TF anodized

Cable Length: 2440 mm or 8ft

Acceleration: 16g max (156.8 m/s²)

Cross-Axis sensitivity: less than 5%

Sensitivity (set up within management software):

± 1.00 Vdc = ± 16g, Resolution 0.004 g

or ± 300 mVdc = ± 4.8g, Resolution 0.0012 g

or ± 100mVdc = ± 1.6g, Resolution 0.0004 g

(all 3 options allow for full 13 bit resolution of ± 4000 counts)

Supply voltage: +4.6 - 5.0 Vdc (X axis only)

All 3 axes powered by X axis plug.

Cross talk: 5%

Accuracy: Better than ± 2 % full scale

100Hz cut off ± 0.5dB

500Hz cut off ± 1dB

1250Hz cut off +1db -3dB

Low pass filtering: 100 Hz, 500 Hz, 1,250 Hz user adjustable via links by removing lid of interface unit. Low pass filtering 8 pole, 8th order 1.2 Elliptic

Shock survival: 500g unit powered, 1000g unit not powered

Environment: Operating temperature 0°C to 70°C

Series 3 Accelerometers

Product #: S3-1000G-HA

Dimensions: L x H x W (0.54 x 0.51 x 0.54 inches)

Weight: 8 grams

Material, Housing/Connector: Titanium alloy

Sensitivity: ±2%

Range, F.S. (each axis): ±1000 G

Sensitivity (set up within management software):

| Channel sensitivity | 1V | 300mV | 100mV |

| Full Scale (nominal) | 1000g | 300g | 100g |

Full Scale Voltage Output: ±1 Volts

Element Natural Frequency, Nom.: 30 kHz

Equivalent Electrical Noise: .007 G, RMS

Linearity: 1 %F.S.

Linearity is % of specified full scale (or any lesser full scale range), zero-based best fit straight line method.

Transverse Sensitivity, Max.: 5 %

Signal Polarity: Positive for motion in direction of arrows etched on housing

Maximum Vibration: 1200 G

Maximum Shock: 5000 G

Temperature Range: -40 to +175 °C

VATS-WB-PKG Whole Body Analysis

Includes Series 2 accelerometer, seat pad and analysis software.

Seat Pad Dimensions: 8 inch diameter and 1/2 inch thick in the center

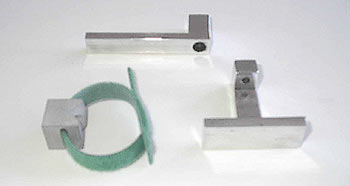

VATS-HA-PKG Hand-Arm Analysis

Includes accelerometer (Series 2 or 3), mounting accessories and analysis software.

Hand-Arm Accessories

Minimum System Requirements

- Microsoft Windows 7, 8, 10 or 11 (64 bit)

- Intel/AMD CPU, dual-core 1.8GHz or more

- 4GB of RAM

- AMD, nVidia or Intel HD Graphics

- 1 free USB port for the Bluetooth adapter class & MicroSD card reader

Request a Quote

Please fill in the form below and click the Submit Request button to send us your quotation requirements. We will reply via email with pricing and delivery information.

Fields marked with an asterisk (*) are required.